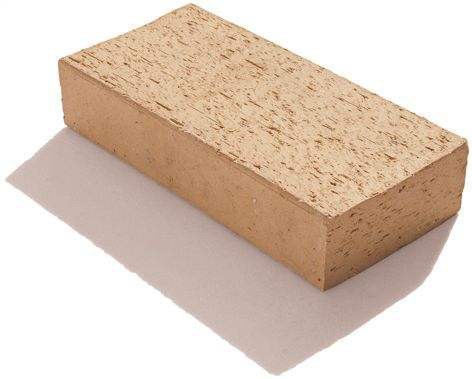

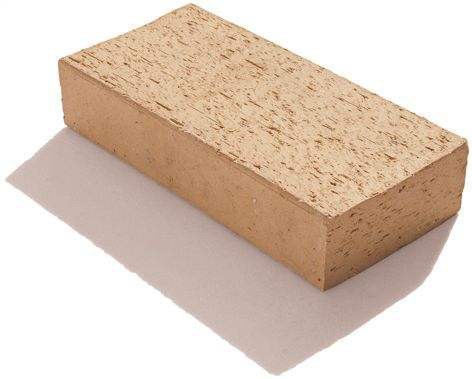

Fired bricks are mainly used for laying load-bearing walls or non load-bearing walls.It is formed from clay as raw material through forming,drying,roasting and other steps,among which the forming step is very important.Let's take a look at its forming process below.

After processing the general raw materials,the molding operation can begin.At present,its body forming method is basically applicable to plastic extrusion molding.There are three types of plastic extrusion molding,namely plastic extrusion molding,semi-rigid plastic extrusion molding,and rigid plastic extrusion molding.These three extrusion molding methods are distinguished based on the moisture content of the molding.When the moisture content of the blank is greater than 16%,it is plastic extrusion molding.When the moisture content of the molded body is 14-16%,semi-rigid plastic extrusion molding is carried out.When the moisture content of the green body is 12-14%,it is extruded into hard plastic.

The formation of fired brick bodies includes:feeding,mixing,adding water,and grinding equipment before the raw materials enter the forming workshop but have not yet entered the extrusion molding brick machine;After being processed by a brick making machine,usable clay strips and wet blanks are formed.Forming should be able to achieve the shape and structure of the product,that is,to form the shape and structure of the product.Therefore,it can be said that form is the foundation.That is to say,the external shape and structure required for the product are molded.In short,molding is a fundamental part of the brick making process.Therefore,the quality of the formed body is directly related to the appearance quality of the finished brick.

The above introduction is about the specific operation of fired bricks in the forming process.From the above content,it can be seen that the molding process is more important,as it directly determines the appearance quality of the finished product.Please follow this website for more content.